In the dynamic world of metal recycling, shearing machines stand out as indispensable tools, facilitating the efficient processing of scrap metal into valuable raw materials. From dismantling obsolete structures to transforming end-of-life vehicles, shearing machines play a pivotal role in the sustainable management of metal waste. Let’s delve into the realm of metal recycling and explore how shearing machines are revolutionizing the industry, one cut at a time.

The Importance of Metal Recycling

Metal recycling is a critical component of the circular economy, offering numerous environmental, economic, and social benefits. By diverting scrap metal from landfills and reducing the need for virgin ore extraction, recycling conserves natural resources, minimizes energy consumption, and mitigates environmental pollution. Moreover, metal recycling contributes to job creation, stimulates economic growth, and fosters innovation in materials recovery and manufacturing processes.

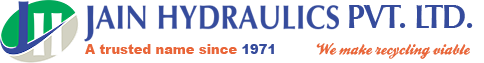

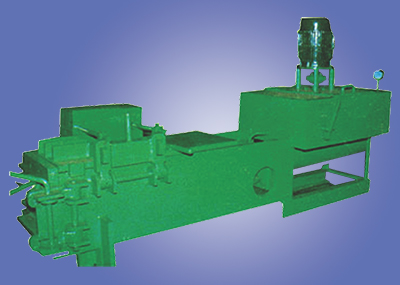

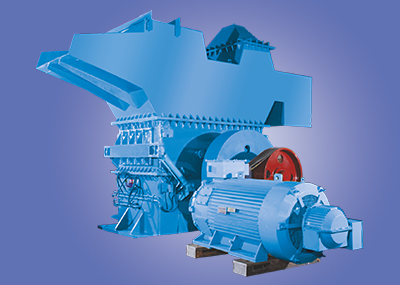

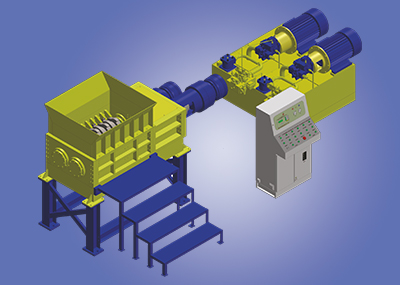

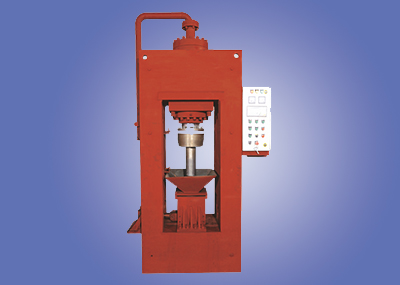

Shearing Machines: A Key Player in Metal Recycling

Shearing machines are essential equipment in metal recycling facilities, where they are deployed for a variety of cutting and processing tasks. These machines are designed to swiftly and precisely cut through various types of scrap metal, including steel, aluminum, copper, and alloys, with minimal material loss or contamination. Whether it’s cutting through thick beams, bulky appliances, or automotive parts, shearing machines excel in handling diverse metal scrap materials.

Applications of Shearing Machines in Metal Recycling

- Automotive Recycling: Shearing machines are instrumental in the dismantling and processing of end-of-life vehicles (ELVs) for metal recovery. They efficiently cut through car bodies, frames, and components, separating ferrous and non-ferrous metals for recycling.

- Demolition and Construction Recycling: In the demolition and construction sectors, shearing machines are employed to dismantle and process metal structures, including buildings, bridges, and infrastructure. By cutting steel beams, columns, and reinforcement bars, shearing machines facilitate the recovery of valuable metals from demolished materials.

- Industrial Scrap Recycling: Shearing machines are utilized in the recycling of industrial scrap generated from manufacturing processes, fabrication shops, and metalworking industries. They help process surplus metal materials, offcuts, and production waste into reusable raw materials, reducing waste and maximizing resource efficiency.

Future Trends and Innovations

As the demand for sustainable metal recycling solutions continues to grow, the future of shearing machines looks promising. Advancements in automation, robotics, and sensor technology are expected to enhance the efficiency, accuracy, and safety of shearing operations. Furthermore, the integration of artificial intelligence (AI) and machine learning algorithms may enable predictive maintenance, optimization of cutting parameters, and real-time monitoring of machine performance.

In conclusion, shearing machines play a vital role in the metal recycling ecosystem, enabling the efficient processing of scrap metal into valuable resources. As industries strive to embrace sustainability and circular economy principles, the importance of shearing machines in metal recycling will only continue to expand, driving innovation and driving towards a more sustainable future.