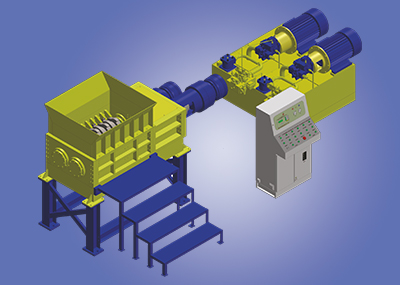

Triple Action Balers

Our journey began way back in 1970s when we manufactured the first single action hydraulic scrap baling press. Today, our vast experience, consistent quality up gradations & continuous R&D has led to the development of the most Rugged and Sophisticated equipment manufactured all across the subcontinent. Our Baling presses enjoy excellent reputation in scrap yards, ferrous processing plants and non-ferrous metal melting plants. They compact virtually all the metal scrap into dense bales. These new generation metal presses / metal compactors set high standards for efficient scrap processing. Our Triple compression scrap baling presses are powerful and efficient in operation. These metal balers produce high-density bales. The higher pressing force and greater output makes these metal balers one of the fastest and the strongest bundle presses / baling presses in India.

For every application there is a suitable scrap baling press. Each scrap baler is equipped with three separately operating compactors that press the scrap material into compact bales. The drive and control concepts of these scrap baling presses allow an efficient operation with particularly low energy consumption and maximum throughput capacity.The carefully planned construction of these metal balers is sturdy and durable due to extensive wear protection. The common wear parts of the compactors can be easily replaced, without having to remove the complete compactor units. The operation and troubleshooting can easily be performed on the multi-information PLC display of the metal baler. The terminal consists of a large display that shows all process-relevant information & status reports.

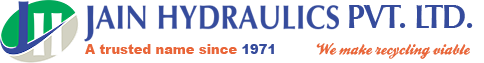

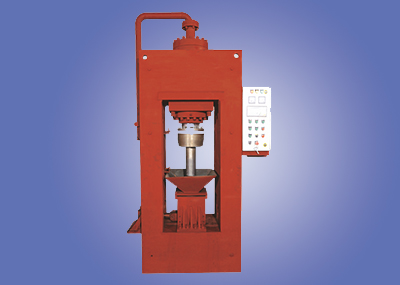

Mini Baler

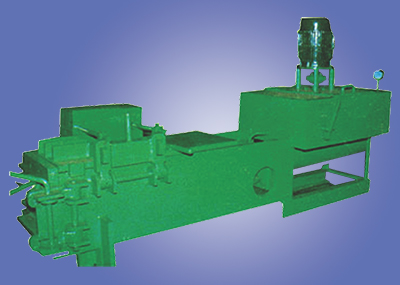

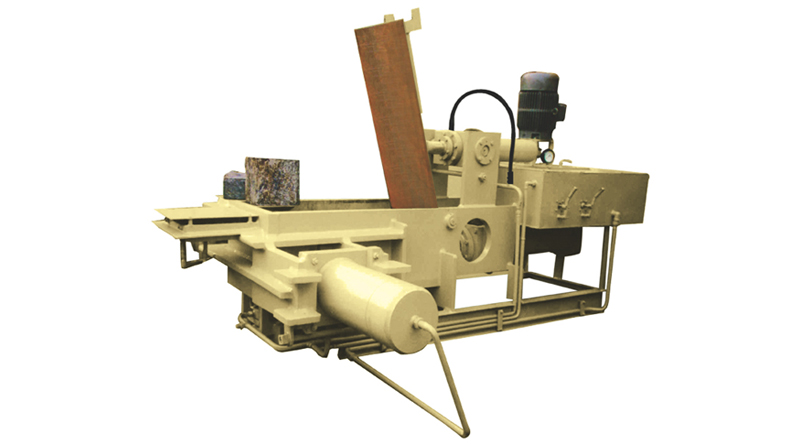

Side Ejection Baler

Top Ejection Baler

Salient Features:

1. Small and Big sized bales resulting the desired output

2. Each scrap baler is equipped with compactors that presses the scrap into high density bales

3. The drive and control concepts of the scrap baling presses allow an efficient operation with particularly low energy consumption and maximum throughput capacity

4. The carefully planned construction of these metal balers is sturdy and durable due to extensive wear protection

5. The common wear parts of the compactors can be easily replaced, without having to remove the complete compactor units

6. The operation and troubleshooting can easily be performed on the multi-information PLC display of the metal baler

7. The terminal consists of a display that shows all process-relevant information and status reports

8. Easily replaceable wear-resistance plates are provided for the long life of the feeding chamber

9. Shearing blades are provided on the edges of the chamber & the partition slide to shear oversized material

10. Efficient after sale service

Benefits:

The “Nut Cracker”brand Triple Action Balers are sturdy & rugged in operation usingthe control panel / remote control of the machine or by the hand levers provided on the machine power pack. These equipment are operational in both Auto &Manual modes. Such balers are best suited to meet the extreme production requirements and produce significant cost savings during the scrap transportation. These baling presses enable the maximum feeding of scrap in the form of large sized bundles in big EAF during one heat. These balers are available in various sizes and with various capacities and can compact virtually all metal scrap such as car body parts, L-2, commercial, HMS, S.S., sheet metals and wire scrap into dense square bales.

Operating Procedure:

1. Once the scrap is charged inside the scrap baling chamber, the top lid compresses the scrap into a closed box

2. The locking cylinder/s then lock the top lid preventing any deflection

3. The main cylinders then compress the scrap from the rear end to the designated point

4. The side cylinder then compacts the scrap from the third direction thereby forming a high-density bale

5. Once the desired pressure is reached, the bale ejection takes place and all the cylinders reverse to their home positions

6. The machine gets ready for the next charge

Technicals

Mini Automatic

| Chamber Size (InchxInchxInch) |

Bale Size (InchxInch) |

Main Motor (HP) |

Bale Weight (KG) | Production/Shift (Tons) | ||||||

| M.S. | Aluminium | Copper | Paper | M.S. | Aluminium | Copper | Paper | |||

| 35x18x18 | 6×6 | 15 | <=15 | x | <=15 | x | <=2 | x | <=2 | x |

| 55x24x18 | 8×8 | 30 | <=30 | <=15 | <=35 | x | <=5 | <=2.5 | <=6 | x |

| 55x24x20 | 10×10 | <=40 | <=20 | <=45 | x | <=10 | <=4 | <=12 | x | |

| 55x24x20 | 12×12 | <=50 | <=25 | <=55 | <=50 | <=12 | <=5 | <=14 | <=10 | |

Mini PLC

| Chamber Size (InchxInchxInch) |

Bale Size (InchxInch |

Main Motor (HP) |

Bale Weight (KG) | Production/Shift (Tons) | ||||||

| M.S. | Aluminium | Copper | Paper | M.S. | Aluminium | Copper | Paper | |||

| 55x30x18 | 8×8 | 15 | <=30 | <=15 | <=35 | x | <=10 | <=5 | <=11 | x |

| 55x30x20 | 10×10 | 30 / 40 | <=40 | <=20 | <=45 | x | <=14 | <=7 | <=16 | x |

| 55x30x20 | 12×12 | <=50 | <=25 | <=55 | <=50 | <=16 | <=8 | <=18 | <=16 | |

Mini Jumbo / Jumbo

| Chamber Size (InchxInchxInch) |

Bale Size (InchxInch |

Main Motor (HP) |

Bale Weight (KG) | Production/Shift (Tons) | ||||||

| M.S. | Aluminium | Copper | Paper | M.S. | Aluminium | Copper | Paper | |||

| 60x30x24 | 12×12 | 30 | <=50 | <=25 | <=60 | <=50 | <=12 | <=5 | <=14 | <=12 |

| 60x36x24 | 14×14/16×16 | 40 | <=80 | <=35 | <=100 | <=50 | <=16 | <=7 | <=18 | <=12 |

| 72x36x30 | 14×14/16×16 | 40/60/80 | <=100 | <=50 | <=120 | <=60 | <=18 | <=10 | <=20 | <=15 |

Super Jumbo / Monster

| Chamber Size (InchxInchxInch) |

Bale Size (InchxInch |

Main Motor (HP) |

Bale Weight (KG) | Production/Shift (Tons) | ||||||

| M.S. | Aluminium | Copper | Paper | M.S. | Aluminium | Copper | Paper | |||

| 84x44x38 | 20×20/22×22/24×24 | 60/80 | <=250 | x | <=400 | x | <=5 | x | <=8 | x |

| 84x60x50 | 22×22/24×24 | 80/100 | <=400 | x | <=600 | x | <=8 | x | <=12 | x |

| 105x50x50 | 30×30 | 100/120 | <=600 | x | <=800 | x | <=12 | x | <=16 | x |

Super Jumbo / Monster / Hulk

| Chamber Size (InchxInchxInch) |

Bale Size (InchxInch |

Main Motor (HP) |

Bale Weight (KG) | Production/Shift (Tons) | ||||||

| M.S. | Aluminium | Copper | Paper | M.S. | Aluminium | Copper | Paper | |||

| 84x44x38 | 20×20/22×22/24×24 | 60/80 | <=250 | x | <=400 | x | <=5 | x | <=8 | x |

| 84x60x50 | 22×22/24×24 | 80/100 | <=400 | x | <=600 | x | <=8 | x | <=12 | x |

| 92x60x48/105x50x50 | 26×26/28×28/30×30 | 100/120 | <=600 | x | <=800 | x | <=12 | x | <=16 | x |

| 135x100x60 | 32×32 | 160 | <=1250 | x | <=1600 | x | <=18 | x | <=24 | x |

* Production depends upon quality & grade of scrap and scrap charging rate

* Above data achieved under ideal working conditions

* Jain Hydraulics reserves all right to change the specifications at any time without any prior intimation

* All data is indicative and not binding