In the world of manufacturing and recycling, metal shredders stand as silent titans, transforming scrap metal into valuable resources while minimizing waste. These robust machines have become indispensable in various industries, offering a sustainable solution for managing metal waste and unlocking new avenues for resource utilization. Let’s delve into the realm of metal shredders, exploring their functionality, applications, and the transformative impact they have on modern industrial practices.

Understanding Metal Shredders

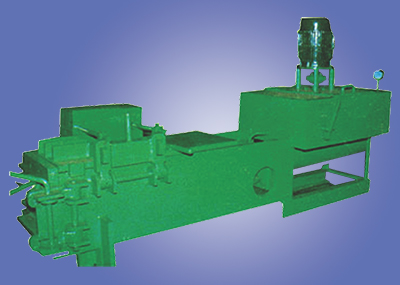

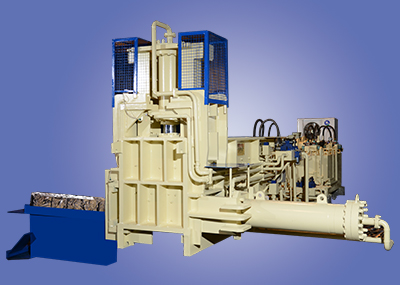

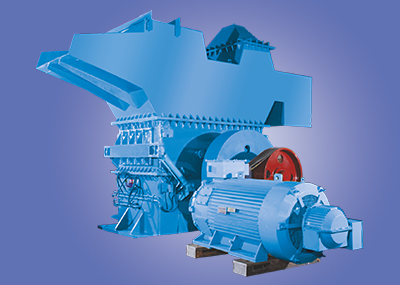

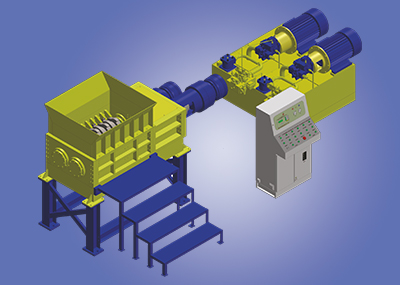

Metal shredders are heavy-duty machines designed to reduce large volumes of metal scrap into smaller, more manageable pieces. Operating on powerful motors and equipped with sharp blades or hammers, these shredders efficiently break down a wide range of metal materials, including steel, aluminum, copper, and more. The shredded metal output can vary in size, from coarse chunks to fine particles, depending on the specific requirements of the application.

Applications Across Industries

1. Scrap Metal Recycling:

Metal shredders play a pivotal role in scrap metal recycling facilities, where they process discarded metal items such as old cars, appliances, and structural components. By shredding bulky metal objects into smaller pieces, these machines facilitate easier handling, transportation, and sorting of scrap metal, thus enabling efficient recycling processes.

2. Steel Production:

In the steel industry, metal shredders are utilized to preprocess scrap metal before it undergoes melting and refining processes. By shredding scrap metal into uniform sizes, these machines enhance the efficiency of steelmaking operations, reduce energy consumption, and contribute to the overall sustainability of steel production.

3. Waste-to-Energy Plants:

Metal shredders are integral components of waste-to-energy plants, where they shred metal-containing waste streams such as municipal solid waste (MSW) and industrial waste. The shredded metal fractions are then separated for recycling, while the remaining waste material is processed for energy recovery through combustion or other conversion technologies.

4. Environmental Remediation:

In environmental cleanup efforts, metal shredders aid in the processing of contaminated materials containing hazardous metals. By shredding and segregating metal-contaminated waste, these machines facilitate the remediation of polluted sites, contributing to environmental restoration and public health protection.

Advantages of Metal Shredders

- Resource Recovery: Metal shredders enable the recovery of valuable metals from scrap, reducing the need for virgin raw materials and conserving natural resources.

- Waste Reduction: By shredding and recycling metal scrap, these machines help divert significant volumes of waste from landfills, mitigating environmental impacts and promoting circular economy principles.

- Energy Efficiency: Preprocessing scrap metal with shredders before melting or refining processes enhances energy efficiency and reduces greenhouse gas emissions associated with metal production.

- Cost Savings: Metal shredders optimize material handling and processing workflows, leading to cost savings through improved productivity, reduced labor requirements, and decreased waste disposal expenses.

Future Outlook

As industries continue to prioritize sustainability and resource efficiency, the demand for metal shredders is expected to rise steadily. Technological advancements, such as the integration of automation, artificial intelligence, and sensor-based sorting systems, will further enhance the performance and capabilities of these machines. Moreover, expanding applications in emerging sectors like electronic waste recycling and additive manufacturing are poised to drive innovation in metal shredding technologies.

In conclusion, metal shredders represent a cornerstone of modern industrial practices, offering a sustainable solution for managing metal waste and unlocking the full potential of recycled materials. With their versatility, efficiency, and environmental benefits, these machines are reshaping the landscape of metal processing and contributing to a more sustainable future for industries worldwide.