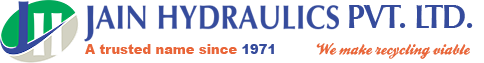

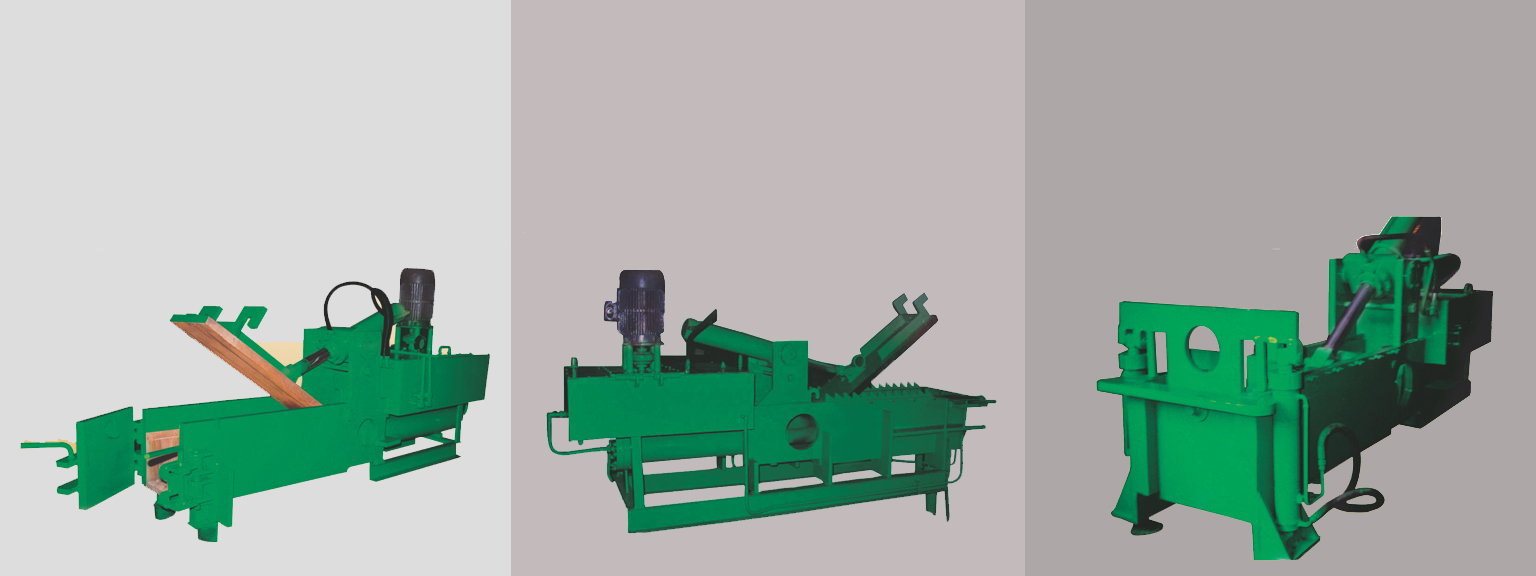

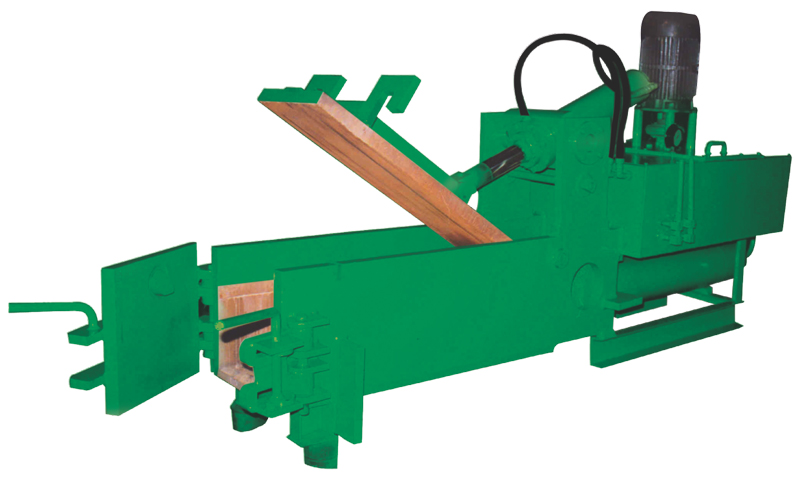

Single Action Balers

Single Action baler was the first compactor manufactured at Jain Hydraulics. Such a baler is basic in design and call for minimal trouble shooting. Small and compact in size, this is best suited for lesser processing applications. Single Action baler is easy to operate and produce considerate cost savings for small traders.

Salient Features

1. Easy to operate by a single, manually operated Direction Control Valve

2. Single compact unit mounted over channel

3. Limit valves & Check valves are provided to avoid any accident

4. No Civil Foundation is required

5. Efficient after sale service

Optional Features

1. Replaceable wear-resistance plates can be provided for the long life of the feeding chamber

2. The machine can be customised as per requirement under the sole discretion of Jain Hydraulics

Benefits

The “Single Action Baler” was the first baling press to be manufactured at Jain Hydraulics in the year 1973. These are the cheapest of all the available models. Such balers are typically maintenance free and call for minimal power consumption. These metal balers are best suited for small processing applications where cheap labour is easily available.

Technicals

| Pressing Chamber Size | Bale Size | Electric Motor | Ferrous | Aluminium | Copper | Lead | Zinc | Tin | ||||||

| Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | |||

| Inch | Inch | hp | Kg. | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift |

| 40x15x15 | 15×15 | 10 | 15 – 20 | 2.4 – 3.2 | 5 – 7 | 0.8 – 1.12 | 17 – 23 | 2.72 – 3.68 | 22 – 29 | 3.52 – 4.64 | 14 – 18 | 2.24 – 2.88 | 14 – 19 | 2.24 – 3.04 |

| 52x15x15 | 15×15 | 15 | 20 – 25 | 3.2 – 4 | 7 – 9 | 1.12 – 1.44 | 23 – 29 | 3.68 – 4.64 | 29 – 36 | 4.64 – 5.76 | 18 – 23 | 2.88 – 3.68 | 19 – 23 | 3.04 – 3.68 |

| 40x18x20 | 18×20 | 10 | 25 – 30 | 4 – 4.8 | 9 – 10 | 1.44 – 1.6 | 29 – 34 | 4.64 – 5.44 | 36 – 43 | 5.76 – 6.88 | 23 – 27 | 3.68 – 4.32 | 23 – 28 | 3.68 – 4.48 |

| 52x18x20 | 18×20 | 15 | 30 – 35 | 4.8 – 5.6 | 10 – 12 | 1.6 – 1.92 | 34 – 40 | 5.44 – 6.4 | 43 – 51 | 6.88 – 8.16 | 27 – 32 | 4.32 – 5.12 | 28 – 33 | 4.48 – 5.28 |

* The above data is indicative & not binding. This does not guarantee or contains assurances of any kind

* The performance data are strongly dependent on the type and composition of the input material, the feeding density as well as the qualification of the operator

* The company reserves all rights to introduce any modifications

* The equipment shall be under warranty for one year against any manufacturing defect from the date of supply

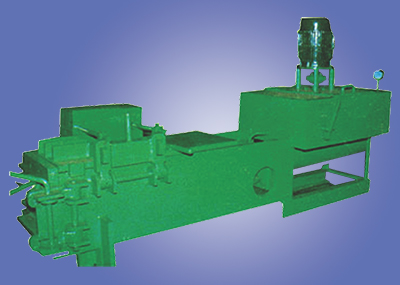

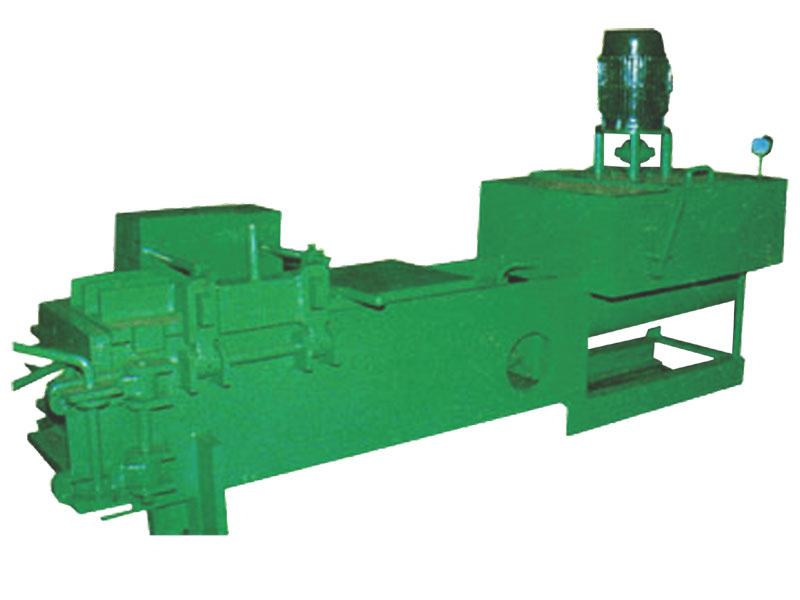

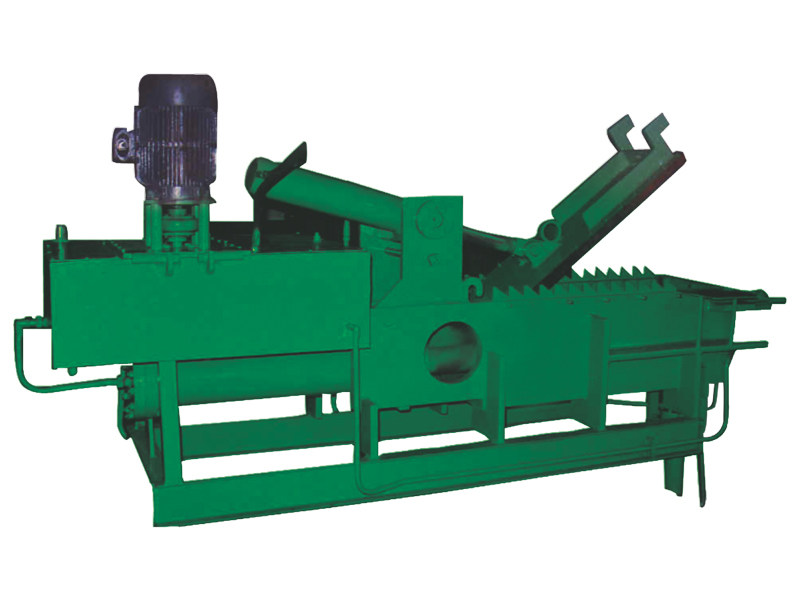

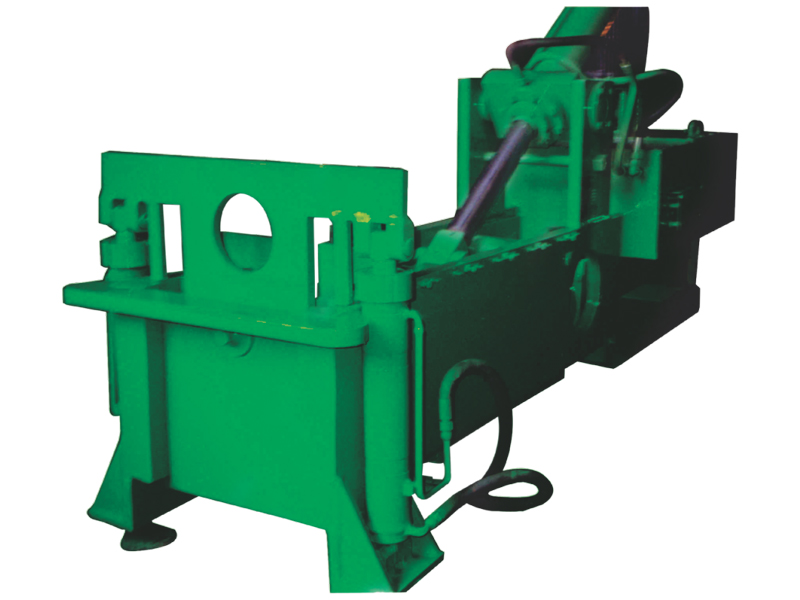

Double Action Balers

A Double Action baler presses the scrap from two sides i.e. from the Top & Length wise. Small & compact, such a baler is best suited for small scrap traders requiring 5-8 tons of light scrap to be processed per shift. The baler is operated by two manually operated Direction Control Valves, one to operate the top lid cylinder& the other to operate the rear pressing cylinder. Basic in design, such balers call for minimal trouble shooting.

Salient Features

1. Easy to operate by two, manually operated Direction Control Valves

2. Easily replaceable wear-resistance plates are provided for the long life of the feeding chamber

3. Best suited for M.S. Turning, Sheet Cutting, L-2, & other ferrous & non-ferrous scrap

4. Single compact unit mounted over channel

5. Limit valves & Check valves are provided to avoid any accident

6. No Civil Foundation is required

7. Efficient after sale service

Optional Features

1. Also available in fully automated PLC controlled mode

2. Shearing blades on the edges of the chamber & the top lid to shear over sized material

3. The machine can be customised as per requirement under the sole discretion of Jain Hydraulics

4. Heat Exchanger to keep the oil cool

Benefits

The Jain Hydraulics “Double Action Balers” are easy & economical in operation by two manually operated direction control valves provided on the power pack of the machine. These balers are typically maintenance free and call for minimal power consumption. Such baling presses are best suited for small processing applications where cheap labour is easily available.

Technicals

| Pressing Chamber Size | Bale Size | Electric Motor | Ferrous | Aluminium | Copper | Lead | Zinc | Tin | ||||||

| Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | Bale Weight | Production / Shift | |||

| Inch | Inch | hp | Kg. | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift | Kg | Tons / Shift |

| 45x15x18 | 10×15 | 15 | 20 – 22 | 4.8 – 6 | 7 -9 | 1.68 – 2.16 | 23 – 29 | 5.52 -6.96 | 29 – 36 | 6.96 – 8.64 | 18 – 23 | 4.32 – 5.52 | 19 – 23 | 4.56 – 5.52 |

| 52 x18x20 | 12×18 | 20 | 30 – 35 | 7.2 – 8.4 | 10 – 12 | 2.4 – 2.88 | 34 – 40 | 8.16 – 9.6 | 43 – 51 | 10.3-12.24 | 27 – 32 | 6.48 – 7.68 | 28 – 33 | 6.72 – 7.92 |

| 52 x24x20 | 12×24 | 20/25 | 40 – 45 | 10.8 – 12 | 15 – 17 | 3.6 – 4.08 | 51 – 57 | 12.24-3.68 | 65 – 72 | 15.6-17.28 | 41 – 45 | 9.84 – 10.8 | 42- 47 | 10.08-11.28 |

* The above data is indicative & not binding. This does not guarantee or contains assurances of any kind

* The performance data are strongly dependent on the type and composition of the input material, the feeding density as well as the qualification of the operator

* The company reserves all rights to introduce any modifications

* The equipment shall be under warranty for one year against any manufacturing defect from the date of supply