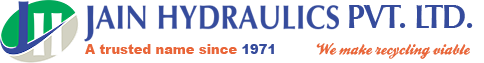

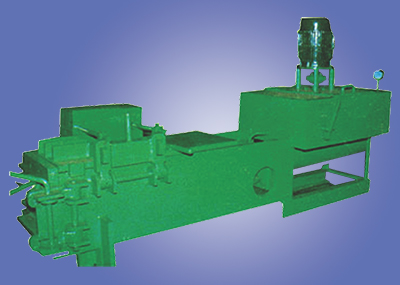

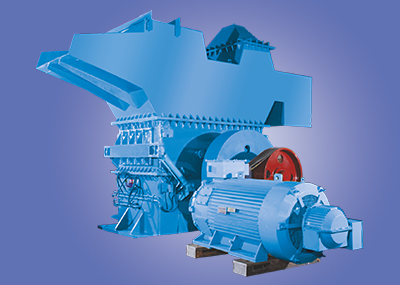

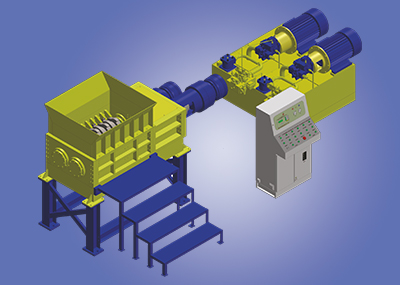

Our journey began way back in 1970s when we manufactured the first single action hydraulic scrap baling press. Today, our vast experience, consistent quality up gradations & continuous R&D has led to the development of Fully Automatic, Extra Heavy Duty Hydraulic Baler-Shears. Our Box Shears enjoy excellent reputation in scrap yards & steel plants. These machines are capable to process various types of scrap like L.M.S, Car Bodies, Bars and H.M.S. etc. These are robust in design with sturdy and powerful side arms, a main pusher cylinder and a very powerful Shear. The drive and control concepts enable baling the scrap, baling and then shearing the scrap or directly shearing the scrap. Free Selection of force and velocity for all press motions result in higher productivity. The length of cut can be decided as required and the machine can be channelled accordingly.

The carefully planned construction of these metal shears is sturdy and durable due to extensive wear protection. The common wear parts of the shears can be easily replaced, without having to remove the complete compactor units. The operation and troubleshooting can easily be performed on the multi-information PLC display of the box shear. The terminal consists of a large display that shows all process-relevant information & status reports.

Salient Features

- Every equipment is robust in design with sturdy and powerful side arm, a main pusher cylinder, two clamping cylinders and a very powerful Shear

- Big scrap feeding chamber enables easy processing of the oversized scrap

- The entire pressing chamber is manufactured using highly wear resistant plates

- The length of cut can be decided as required and the machine can be channelled accordingly

- The drive and control concepts of the machine allow an efficient operation with particularly low energy consumption and maximum throughput capacity

- The carefully planned construction of these metal shears is sturdy and durable due to extensive wear protection

- The operation and troubleshooting can easily be performed on the multi-information PLC display of the metal baler

- The terminal consists of a large display that shows all process-relevant information and status reports using the position monitoring systems

- Efficient after sale service

Benefits

Our “Baler Shears” are sturdy & rugged in operation by the joy sticks & the push buttons provided on the control panel of the machine. These giant equipment are operational in both Auto & Manual modes. Such shears are best suited to meet the extreme production requirements and produce significant cost savings during the scrap transportation. These shears enable the maximum feeding of scrap in furnaces during one heat. These shears are available in various sizes and with various capacities and can cut virtually all metal scrap such as car bodies, HMS, bars etc.

Sequence of Operations

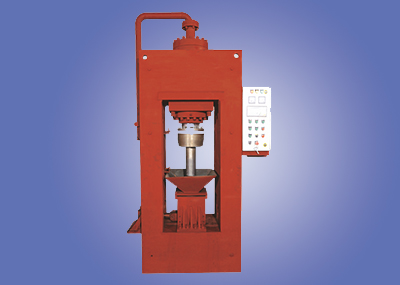

We offer you a Fully Automatic, PLC controlled, Extra Heavy Duty Hydraulic Shearing Machine (Baler-Shear) to shear the over-sized ferrous scrap. The machine will be rigid and sturdy in construction with heavy ribs and stiffeners to bear the overall load and the machine will be complete in all respect with hydraulic power pack, control panel, oil tank, heat exchanger, and pressure gauges. Our Baler Shear is a state of art equipment which used to shear the scrap. The sequential operation of the machine is as under;

- The scrap is charged inside the pressing chamber

- The arm cylinders press the scrap from the top

- The side cylinders then press the scrap from the side thereby closing the charging box

- A scrap log is formed with width of the log equal to the width of the shear mouth

- The machine is then set to “auto on” mode

- The pusher cylinder first compresses the scrap (if the machine mode is selected on “Baling-Shearing”) to make a dense bale and then moves the scrap forward to a pre-set distance under the Shear head (length of cut adjustable)

- After clamping the scrap, the heavy-duty shear then comes down and cuts the scrap

- The baled scrap is sheared and sized as per requirement

- The process of pushing and cutting likewise goes on till the entire scrap gets cut into even size portions

- Meanwhile, the scrap for the next cycle is charged in the hopper area created in the machine

- After completion of the ongoing shearing cycle, all the cylinders reverse to their initial positions. Once the chamber opens, the scrap for the next cycle automatically falls inside the baling chamber and the machine gets ready for the next cycle